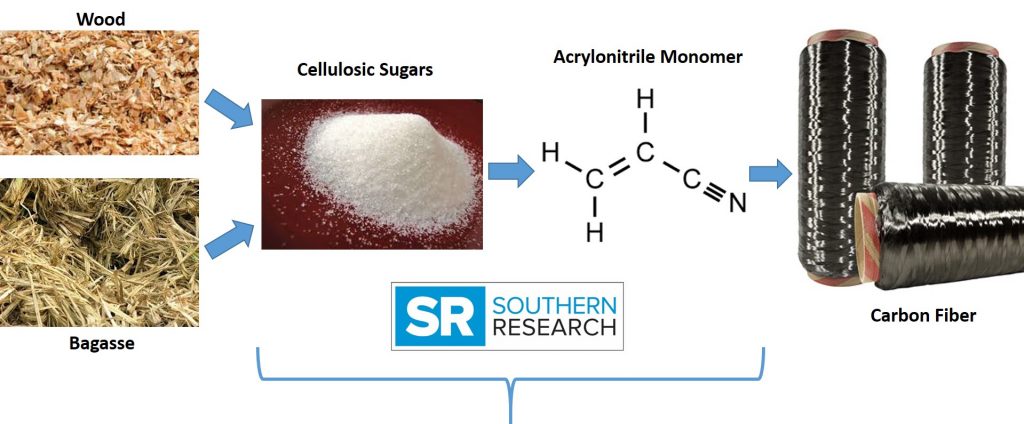

Amit Goyal, Ph.D., is leading a team of scientists at Southern Research that has developed a cheaper and cleaner process for making acrylonitrile, a precursor for carbon-fiber production.

Goyal’s team has devised a multi-step catalytic process that converts sugars from non-food biomass to acrylonitrile through a pathway that could be around 20 percent cheaper than the typical production method. Their process also involves a substantial reduction in greenhouse gases.

The carbon fibers produced from this raw biomass process could interest automakers, which are looking at composite materials to reduce the weight of vehicles.

Goyal, manager of Southern Research’s sustainable chemistry and catalysis group, Energy & Environment, North Carolina, acts as principal investigator on the $6 million Department of Energy study.

Goyal and Tim Hansen, a Southern Research Energy & Environment director in North Carolina, discussed the project with Susan Neylon of ITECS, a management consulting firm that specializes in technology development. The interview was featured on the ITECS blog.

Susan Neylon – Tell our readers about the DOE-EERE program that you are working on.

Amit Goyal – We developed a process that is a multi-step catalytic process for conversion of sugars from non-food biomass to acrylonitrile at mild conditions. In the first reaction step, sugars are converted to oxygenates. These oxygenates are than converted to an intermediate which eventually is converted to acrylonitrile.

Susan Neylon – What is the advantage of this pathway?

Tim Hansen – It is anticipated that the cost of the acrylonitrile produced this way will be potentially ~15-22% lower than the average price of traditional acrylonitrile with a 37% reduction in green house gases.

Susan Neylon – What are your commercialization targets?

Tim Hansen – The end use of the carbon fibers produced from this method will be applications to light-weight automobiles. It is anticipated that the need for carbon fiber in this market will cause an annual increase of 11-18%. However, the traditional production of carbon fiber is highly dependent on petroleum-based propylene production, which is reduced due to the growth of natural gas.

Susan Neylon – How far are you away from getting a carbon fiber made with this precursor on a vehicle?

Amit Goyal – We are approaching Phase 2 of the technology development expected start date is early 2017. We would like to have a pilot plant for the technology up and running within the next 30 months.

Tim Hansen – Southern Research would not commercialize this technology by itself. They either would license the technology, do a joint venture or spin it out as a separate entity. Right now they are working with Cytec- Solvay group which will take the precursor and validate its quality to produce carbon fibers. This product will then be compared with the petroleum-based acrylonitrile.

Susan Neylon – How will the project be funded?

Amit Goyal – We have a $6MM program with the department of energy. We also have cost share from Southern Research, Cytec and the NJ Institute of Technology.

Susan Neylon – What is the NJ Institute of Technology role?

Amit Goyal – They are doing the material characterization.

Susan Neylon – What keeps you up at night?

Amit Goyal – We believe and hope this will be the one of the first thermocatalytic process to be commercialized for selective production of a chemical from raw biomass.

Tim Hansen – The front-end economics of the feedstock. What will they be? Will it be stable? Will we have the same problems as propylene with price volatility?

Susan Neylon – I wish you luck. I know that it has been a long term dream of the DOE to make low cost carbon fiber. Hopefully this technology will be one of the answers to that dream.