A Southern Research scientist who developed a process that could lead to low-cost carbon fiber won a “Shark Tank”-style pitch competition at the World Bio Markets 2017 conference, an event that attracts innovators, investors and industrial leaders from around the world.

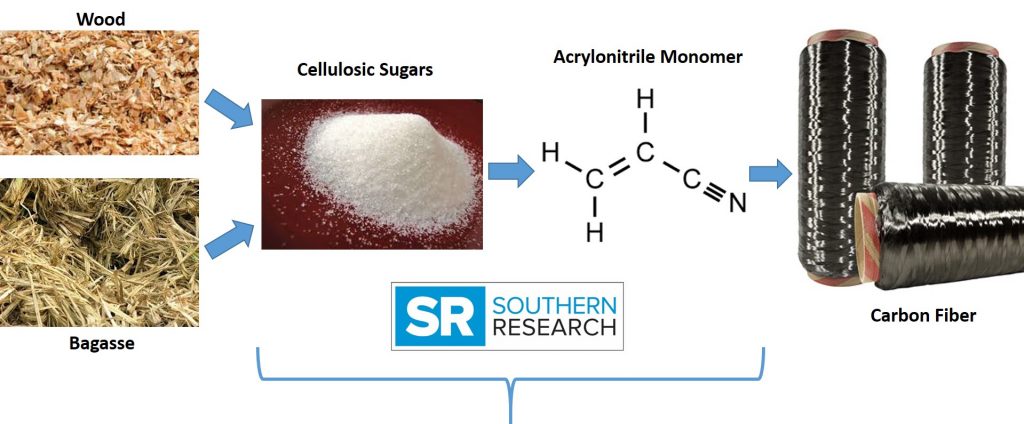

The technology pioneered by Amit Goyal, Ph.D., manager of sustainable chemistry and catalysis in Southern Research’s Energy & Environment division, converts non-food biomass into a colorless liquid called acrylonitrile that’s used in making artificial fibers.

The process developed by Goyal’s team produces acrylonitrile that is around 20 percent cheaper than conventional production methods. It’s also a lot cleaner, with a 37 percent reduction in greenhouse gases.

A panel of five judges in the World Bio Markets’ “Shark Tank” competition on March 29 in Amsterdam selected Southern Research’s technology over those pitched by bio-fuel firms based in India and Mexico. Contestants got seven minutes to make their case to the judges, who then had five minutes to ask questions and comment.

The judges, primarily bankers and venture capitals, picked the winning technology based on its investment potential and the likelihood it will reach commercial scale.

“I am really proud of Amit and pleased to get this positive feedback from the market,” said Bill Grieco, Ph.D., vice president of Southern Research’s E&E division. “We know that Amit and his team are solving important sustainability problems with cost-effective chemical processes, but there is no substitute for strong interest from potential customers and investors to show that our biomass sugar to chemicals technology is headed in the right direction.”

LINKING THE SOLUTION

Goyal said the victory represents a strong endorsement of the work being done by his team at the Birmingham-based non-profit organization’s E&E lab in Durham, North Carolina. He said he hopes the validation adds momentum to the team’s goal of eventually commercializing the technology.

“I really appreciated the feedback from industrial professionals and investors who have actually looked at several such technologies,” he said. “It’s very valuable for us.”

Goyal said the World Bio Markets “Shark Tank” judges carefully considered the viability of the technologies in the competition, including factors such as the cost and availability of raw materials, potential buyers, and projected growth metrics.

“So they really wanted to link the solution – the uniqueness of your technology – with the rest of the pieces of the puzzle,” he said. “They were essentially looking for something they could invest in that has low risk and flexibility.”

World Bio Markets has been called the “Paris Airshow of the bio conference world,” referring to the high-level gathering for aerospace industry leaders. Word Bio Market conferences have attracted speakers including former U.S. Vice President Al Gore and humanitarian Sir Bob Geldof, along with the top thinkers in renewable energy.

This year’s conference, which took place March 27-29 at Amsterdam’s NH Grand Hotel Krasnapolsky, attracted more than 500 professionals in search of partnerships, investment opportunities, biotech breakthroughs, and innovations.

CAPITALIZING ON INTEREST

The U.S. Department of Energy selected Southern Research in 2014 for a $6 million project to advance production of high-performance, low-cost carbon fibers from renewable biomass feedstocks.

As part of this project, Goyal’s team devised a multi-step catalytic process that converts sugars from non-food biomass to acrylonitrile, a key precursor for strong, lightweight carbon fiber.

Traditional, fossil fuel-based production methods for carbon fiber have limited its use, but industrial demand for the material continues to surge in fields such as aerospace, automotive, and wind turbine production. Use of carbon-fiber composites by automakers alone is expected to rise by 11 to 18 percent annually.

Goyal, the principal investigator on the DOE project, said its first phase is complete through the demonstration of the validity of the biomass production process. He expects to launch the second phase – a pilot plant to scale up production – in coming months.

“There’s a lot of interest from industry, and a lot of interest from investors. We hope we can capitalize on that,” he said. “I’m very optimistic.”